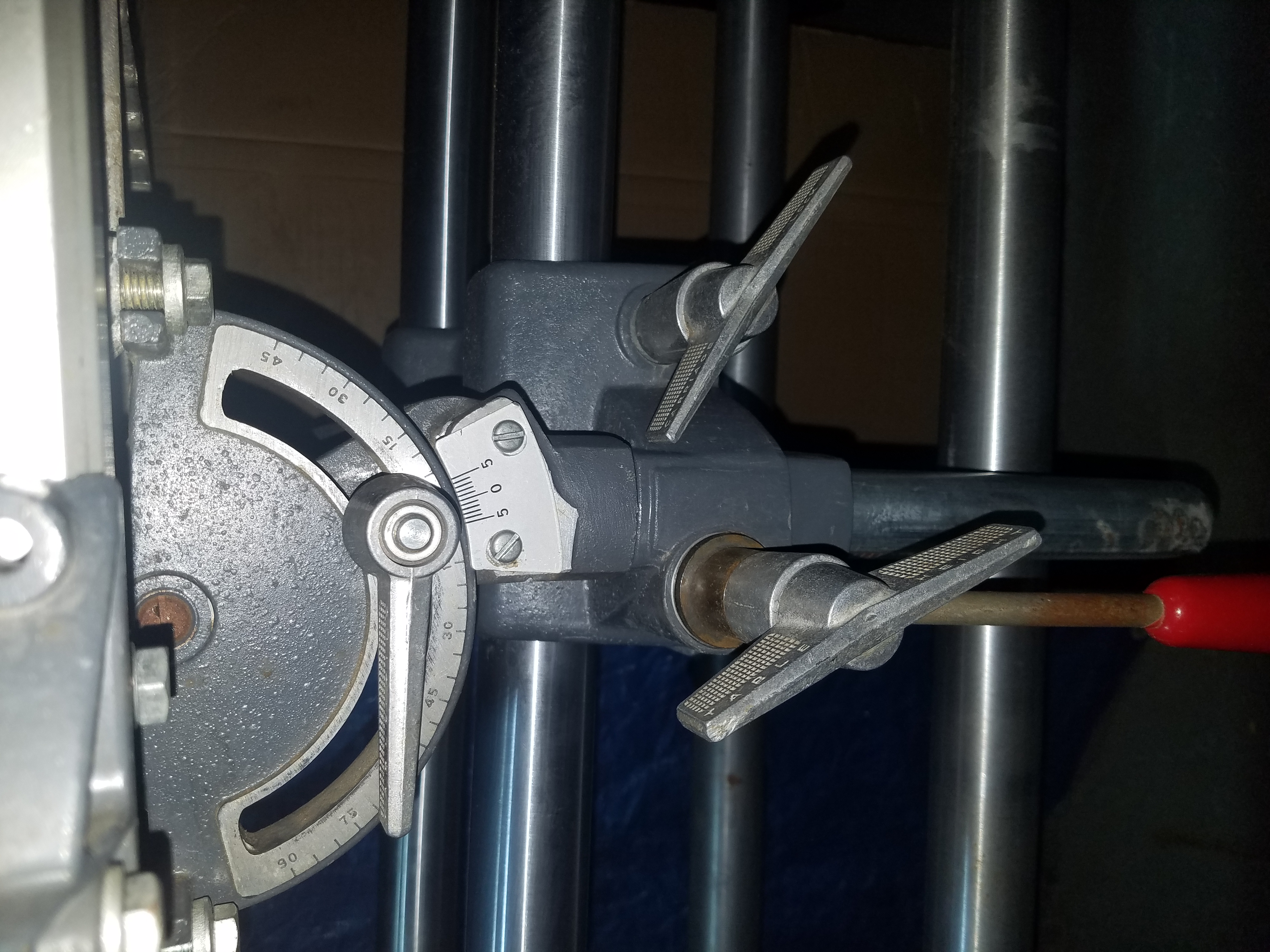

Head unit, polished way and bench bars

This Shopsmith is in great conditon. It was used only a few times in 2020, and it has been used a few times this year. I would keep it, but I have no need of it at this time. It has served me well, and will continue to serve the new owner. The great price ($450)is attributed to CV 19 and the fact our governor has forced me to downsize.

This Shop Smith spent most of it's life as a drill press. It was used for drilling accurate holes in plastic, aluminum, wood, mild steel, and stainless steel. It was occasionally used as a table saw, however, since I have a separate table saw the saw portion had little use. The way tubes and the bench tubes were taken out and polished. The entire machine was cleaned and reassembled in November of 2020. It saw regular use up until last year when our governor labeled my business as non essential, so it saw very little use last year. This is still a reliable machine, and if I was not forced to downsize it would still see regular use. It was last used to drill some plastic in Dec of 2020, and cut some wood Feb 2021.

Some items were damaged or missing when I bought it. The extension table (end broken off), but still works fine; and the main table was damaged. I replaced the main table, and now the fence properly aligns with the table and saw. I also replaced the chuck, key, handle, locking handle. It was important to me to have a working machine, and in some cases I recently replaced parts so that the new owner would have a more comlete tool.

Missing pieces from an original Shop Smith: no lathe pieces (except for tail stock), no sanding disc.

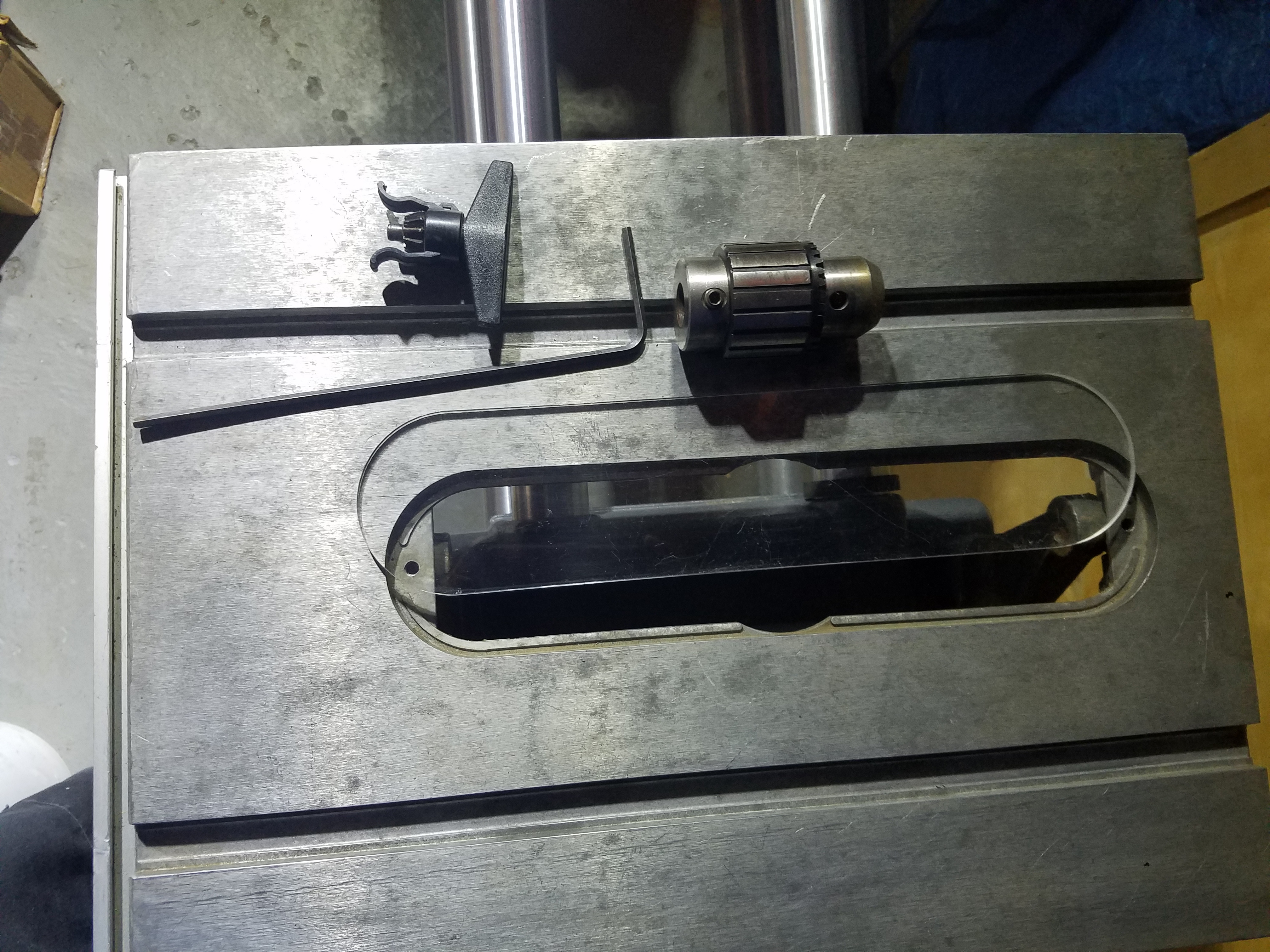

I also had a clear insert made for the table so that when using the drill press I could light the part from both sides.

The old table was damaged when I received it, and these pictures were taken before I installed the new table. There are pictures with the new table, which aligns the fence properly with the saw blade. The old table will be available for sale as a separate item.

Jacobs Drill Chuck, Allen, Key, Clear Insert - Old Table

Jacobs Drill Chuck, Allen, Key, Clear Insert - Old Table

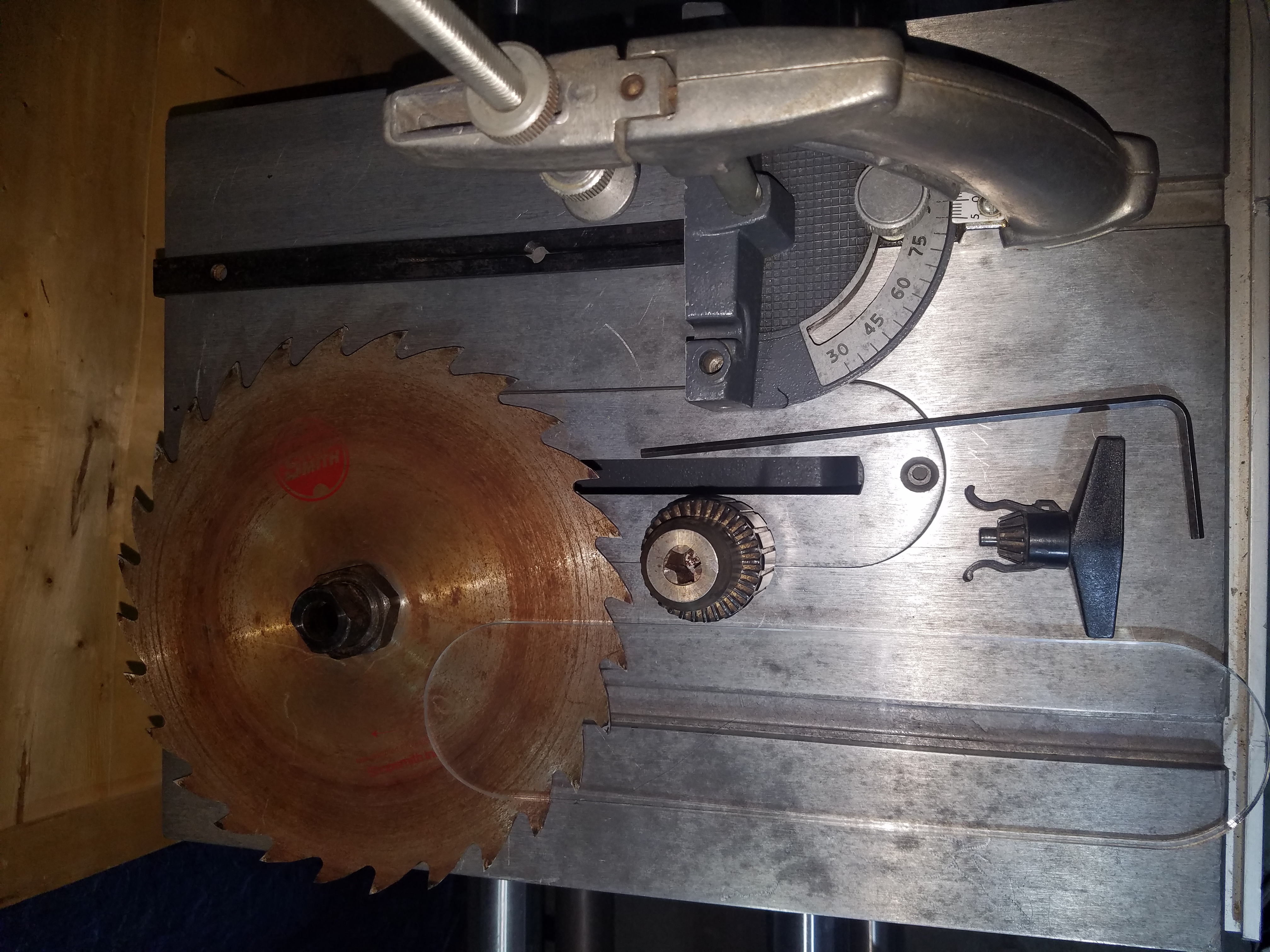

Blade, Arbor, Chuck, Key, Allen, Miter, Saw Insert, Clear Insert - Old Table

The Shop Smith uses a special arbor for the saw blade. Also these blades rust really quick. As soon as you cut something with them, it cleans off the blade. I sometimes would cut a scrap piece of wood to clean off the rust. Shop Smith blades and other parts are readily available online. They also make an arbor that allows the use of other blades that don't have the large Shop Smith hole. This picture includes almost everything that comes with it but the fence.

This is the Shop Smith V 500 series, and it contains the 1 1/8 HP motor.

New table and fence

Head Stock and handle

Quill retracted, you can see there are no gauges on the spindle where the arbor or Jacobs chuck are mounted

The speed control works smooth and easy. I often used it to adjust for the various materials I worked on. If you experience some stiffness in adjusting the speed control, there are 2 areas that a drop of oil will fix. Plenty of information on the Internet on proper oiling of the speed control. My friend had one that the speed control was completely frozen, a few drops of oil fixed it right up. There are access covers that only require removing a few screws to get in and oil the speed control mechanism. No need to disassemble the machine. This should be done about once per year. I did not do it last year, but speed control works fine.

Caution: never turn the speed dial when the quill is not turning. You will cause expensive damage.

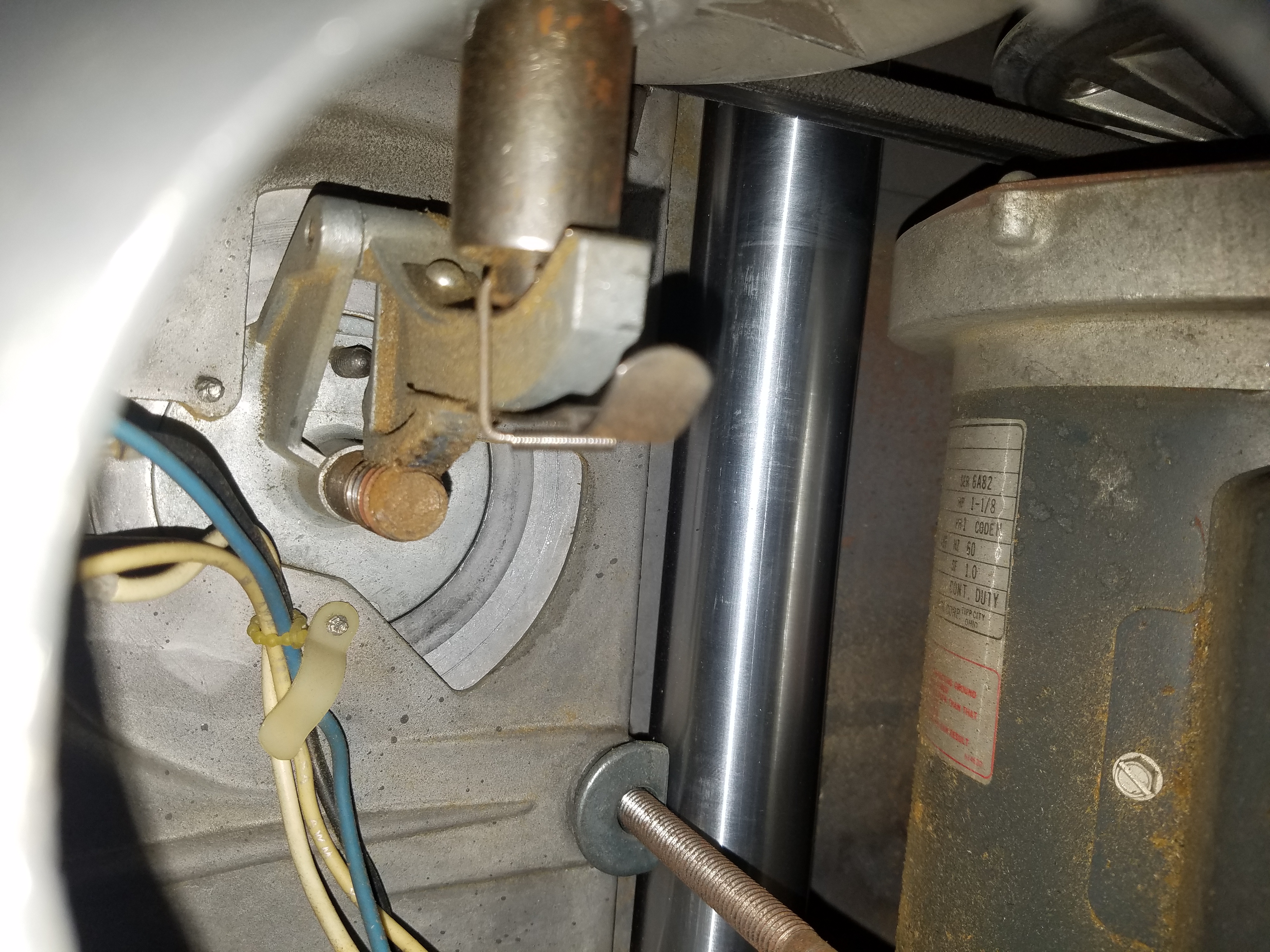

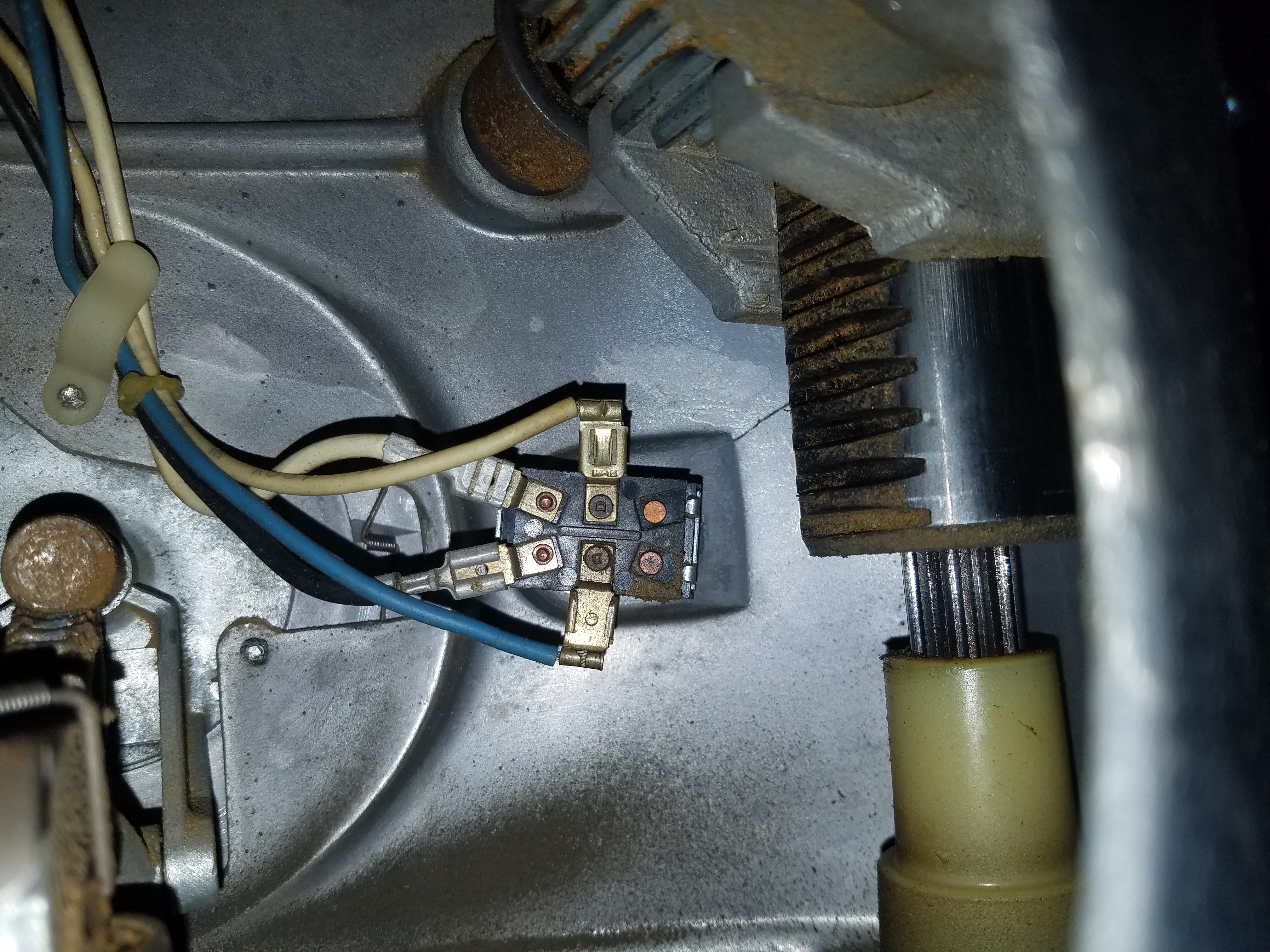

inside view of motor, wiring, polished way tubes

Speed control pulleys and belt

End of the Speed control gear

Not a lot of room to get inside and take pictures, but if the motor ever required servicing the covers to the head stock are removable with only a few screws.

Motor HP = 1 1/8 - Motor serial = 6A82

New Table with a straight fence rail.